Through moist, porous, nutrient-rich and active microorganism filter layer, the odor substance can be decomposed into non-toxic and harmless simple inorganic substances by the adsorption and degradation of the odor substance by biofilm. The biological filter is suitable for low to medium concentration of odor environment. The biological deodorization process is mainly carried out into three steps:

(1) Extracellular adsorption: when passes through the biofiller, the odor substance is adsorbed by the efficient functional microorganisms attached to the surface of the filler, the extracellular polymers and the enzymes produced by the metabolism.

(2) Biological absorption: odor substances adsorbed on the surface of microorganisms are transferred into the cells.

(3) Biological oxidation: odor substances are decomposed into non-toxic and harmless water, carbon dioxide or inorganic salts in the metabolic cycle of microorganisms. Organic fillers provide inorganic salts, minerals and partial carbon sources for microorganisms to promote reproduction of microorganisms.

Good purification effect.

Low energy consumption and low cost.

Environmentally friendly, no secondary pollution.

The operation is simple and low maintenance workload.

It is suitable for odor treatment occasions with medium and low concentration odors of various air volumes.

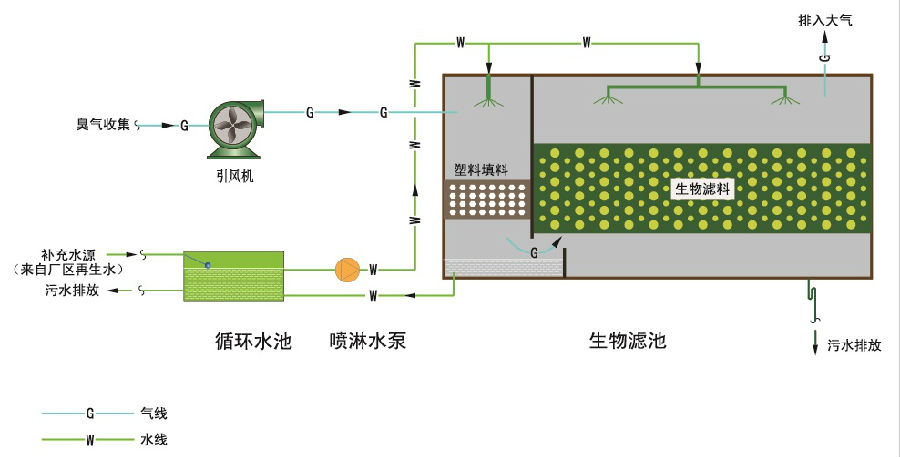

The odor from the collection system enters the pre-wash tank through the fan, which washes away some water-soluble substances and dust, and regulates the gas temperature. After sufficient pre-washing, odor enters the biological filter, through the adsorption and degradation by the microbial filter layer, it finally be decomposed into the gas that meets the standard, and is discharged into the atmosphere through the exhaust port.

It can deal with varieties of organic and inorganic gases, and has great impact load resistance capacity. Applicable to municipal sewage treatment plants, pumping stations, sanitation (including garbage collection, leachate, transfer station), light industry and daily chemical industry, printing and dyeing wastewater plant, petrochemical wastewater plant, hospital wastewater plant, chemical plant, sludge treatment plant, etc.

| Device model | Processing capacity (m3/h) | Outer dimensions (L × B × H, m) | Total operation (KW) |

| NFBU-L-3000 | 1000-3000 | 4.1 × 2.6 × 3.0 | 4.55 |

| NFBU-L-5000 | 3000-5000 | 5.7×2.6×3.0 | 6.25 |

| NFBU-L-8000 | 5000-8000 | 7.3×3.3×3.0 | 12.1 |

| NFBU-L -10000 | 8000-10000 | 7.3 × 4.1 × 3. | 12. |